Fire without flame - sounds paradoxical and is at the same time a groundbreaking discovery. This combustion principle, which finds a wide range of applications in numerous variants, especially in the steel industry and in burners for heat treatment, has unbeatable advantages. Unlike conventional burners, the sophisticated mixing of fuel gas, combustion air and recirculating exhaust gas in WS burners in FLOX® operation avoids peaks in combustion temperature. Thus, despite the application of high air preheating rates to significantly increase efficiency, the simultaneous increase in NOx emissions can be avoided. In addition, the homogeneous temperature distribution in the kiln ensures high-quality products as well as significantly reduced burner wear. All important factors for environmentally oriented thinking, economic action and the manufacture of high-quality products.

However, the potential of FLOX® technology is far from exhausted. In various national and international projects - partly supported by corresponding subsidies - the focus is on future fields of heat process and energy technology. For years, we have been focusing in particular on adapting our burners to the special requirements of green fuels such as hydrogen, ammonia or methanol.

"FLOX®" = "FLameless OXidation": The registered trademark and patented technology of WS Wärmeprozesstechnik GmbH. Potential NOx problems are finally defused and an energy-efficient and functionally reliable system operation for a sustainable

Productivity established.

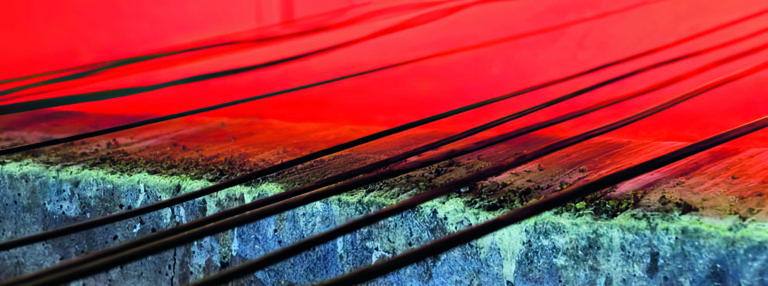

Highly efficient, low-emission and future-proof burner technology from WS Wärmeprozesstechnik is used in an innovative wire annealing furnace of the Künne Group.

Highly efficient, low-emission burner technology from WS Wärmeprozesstechnik that is extremely future-proof due to its hydrogen capability is used in a roller hearth furnace for Schaeffler.

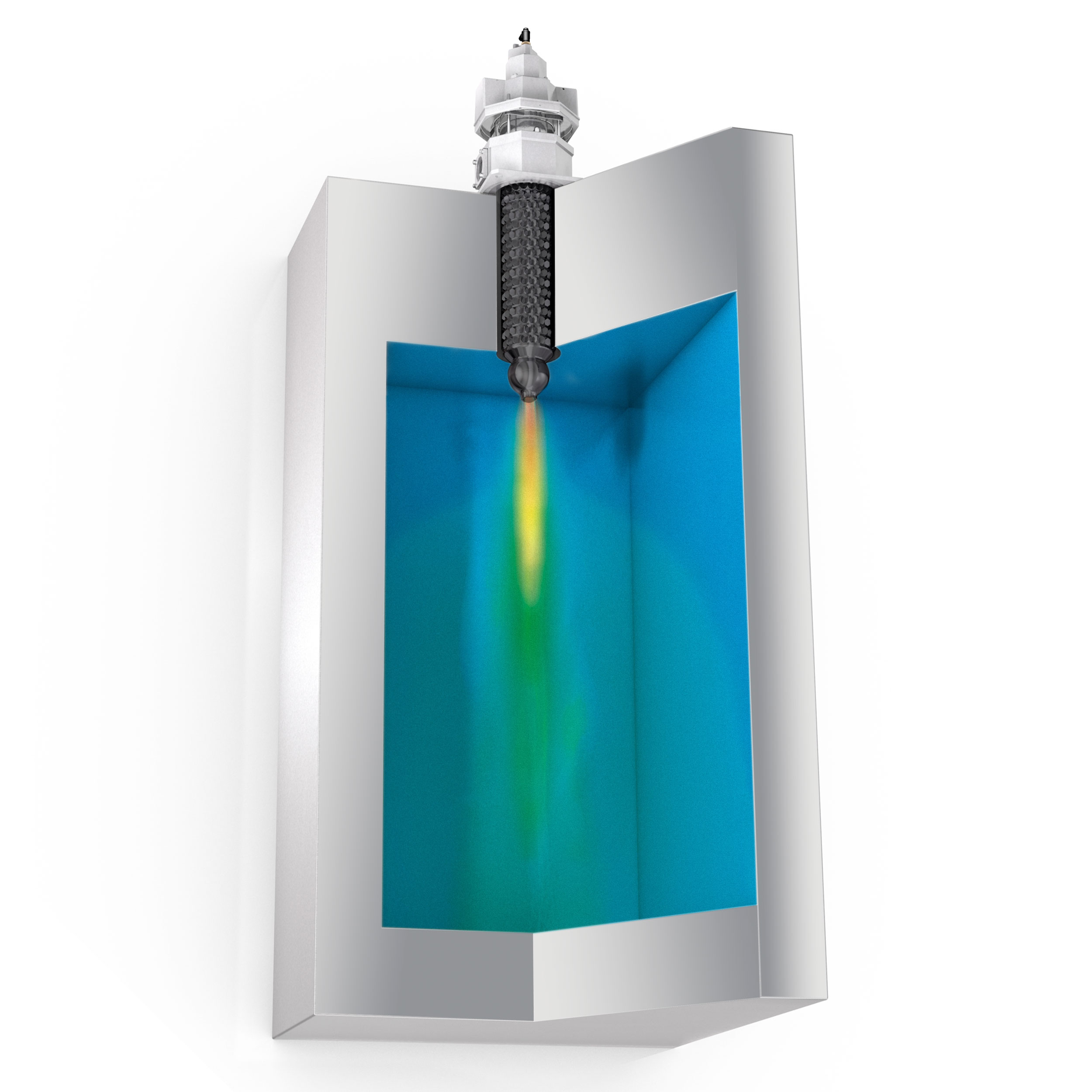

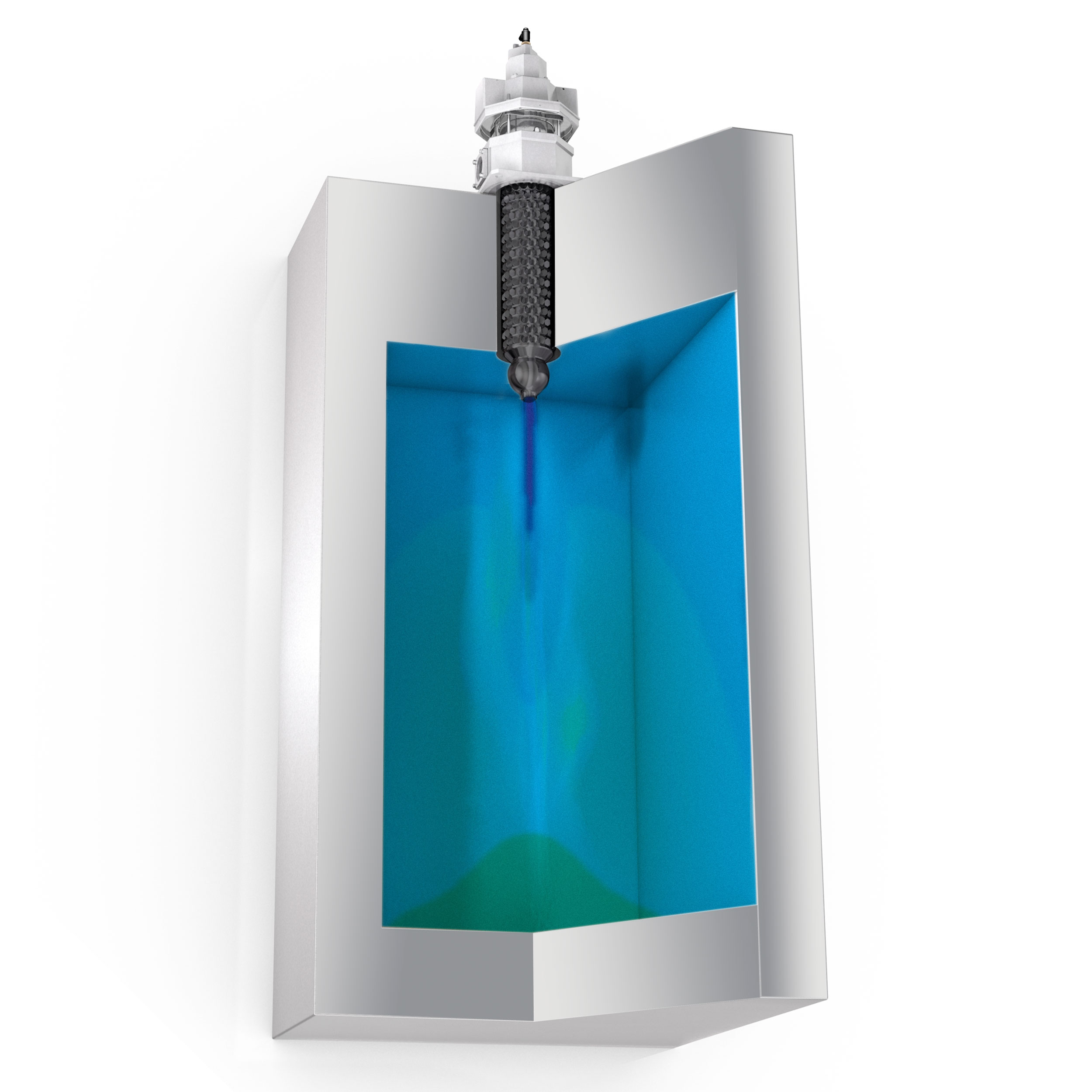

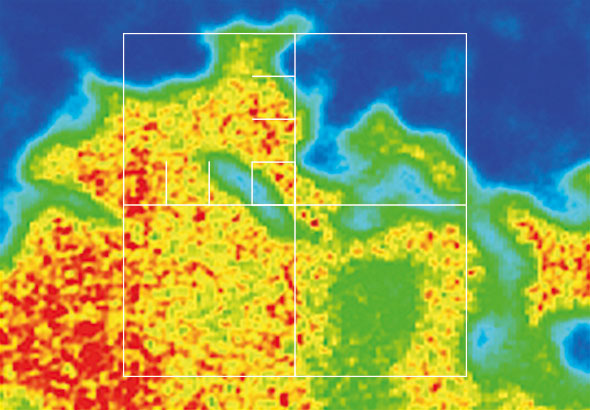

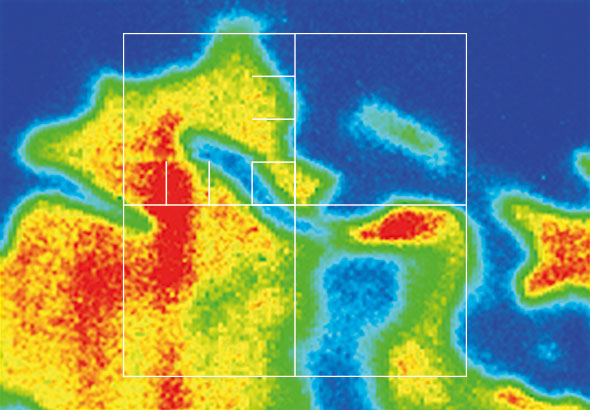

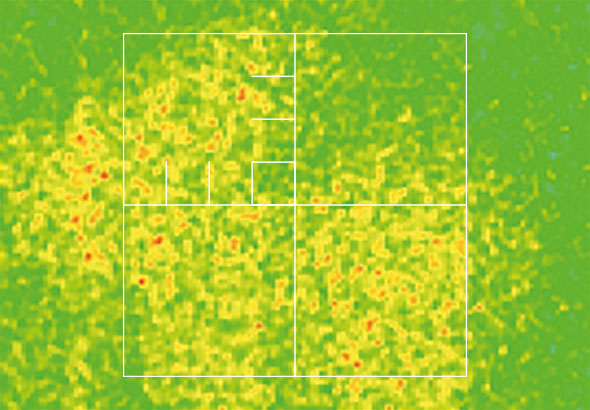

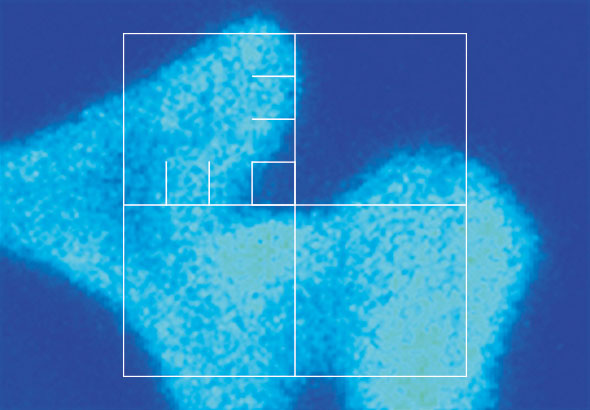

Temperature scale from 600 °C to 2.100 °C

Temperature Flame Mode | Zoom: 10 x 10 mm

OH-Intensity flame mode | Zoom: 10 x 10 mm

Temperature FLOX® Mode | Zoom: 10 x 10 mm

OH-Intensity FLOX® Mode | Zoom: 10 x 10