Burner Controls

WS burner controls provide safe operation of your WS burner. Project specific configuration for seamless commissioning.

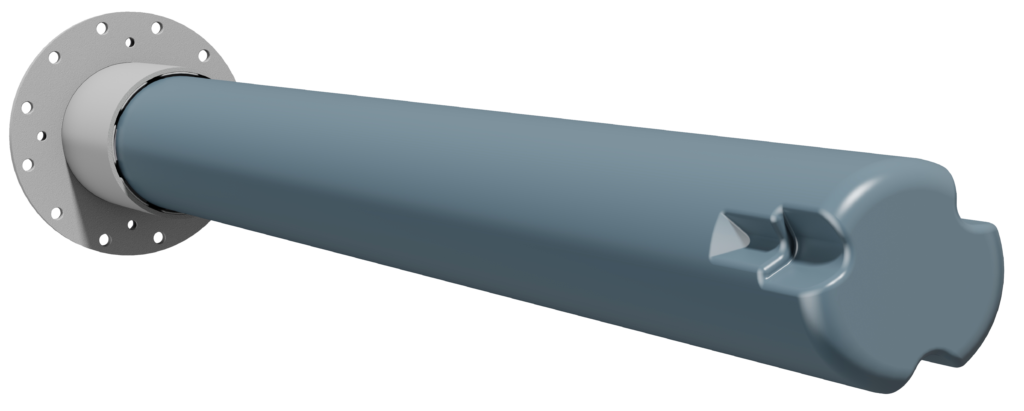

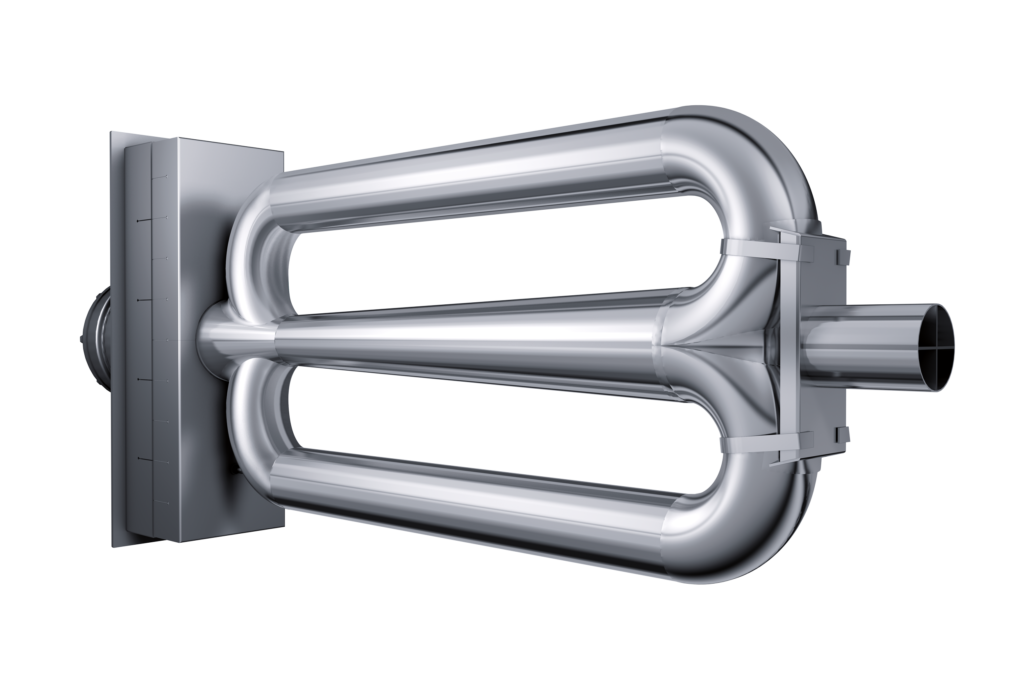

The efficiency of indirect heating depends not only on the burner used, but also to a large extent on the radiant tube. Depending on the requirements, metallic or ceramic radiant tubes of different sizes and designs are used.

WS mastered the challenge of connecting a ceramic tube to a metallic flange with flying colors early on and has relied on the patented connection ever since.

The high temperature resistance of our SiSiC radiant tubes enables extremely long tube service lives. The technical properties also allow easy installation without counter bearings.

Today, WS manufactures ceramic radiant tubes in various diameters up to a standard length of 2,800 mm. Special sizes are available on request.

In addition to straight metallic radiant tubes, WS is pleased to offer its customers recirculating type P and double P radiant tubes. Due to the greatly improved temperature uniformity compared to non-recirculating tubes, WS radiant tubes achieve particularly long service lives and enable minimal NOx emissions with high burner efficiency.

Steel industry and heat treatment

Chemical Industry

Ceramic Industry

WS burner controls provide safe operation of your WS burner. Project specific configuration for seamless commissioning.

Perfect accessories suitable for your WS burner system: radiant tubes, controls, spare parts and valve trains.