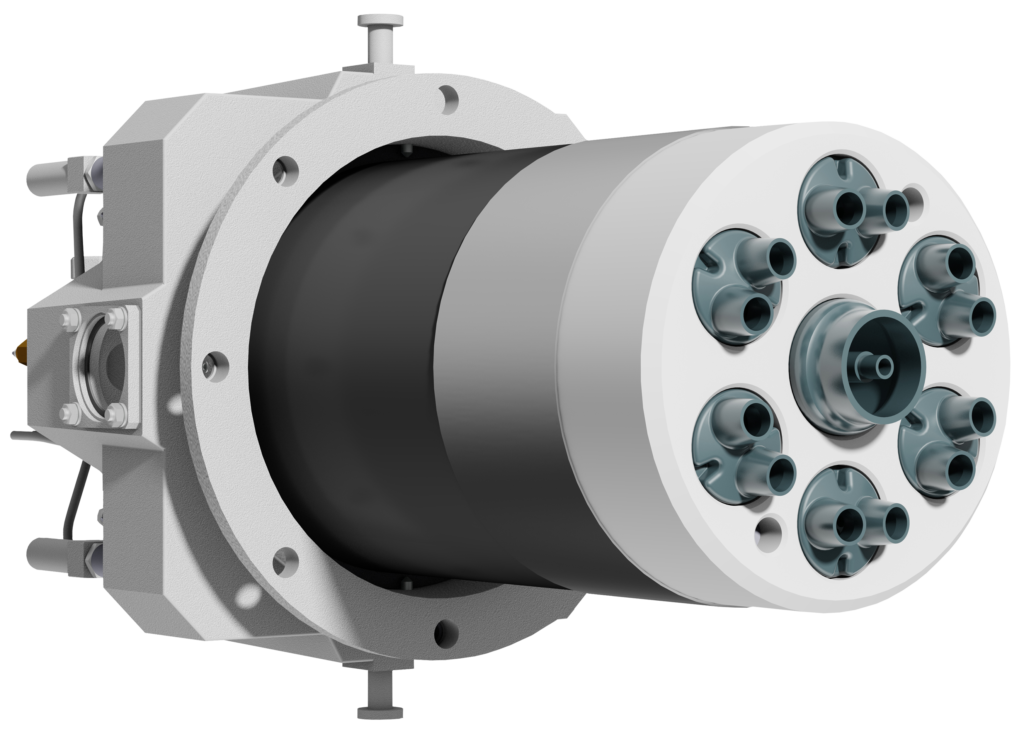

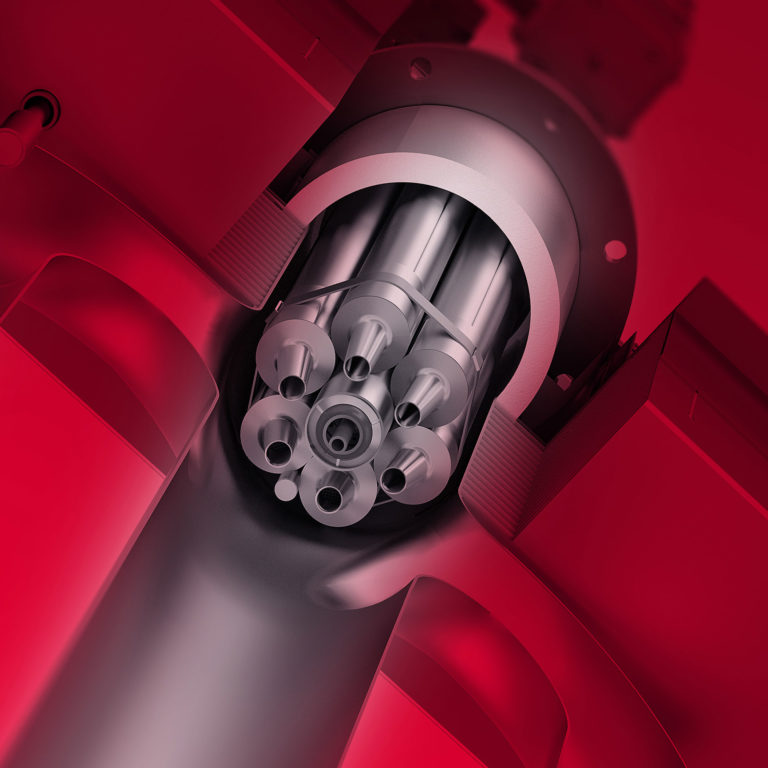

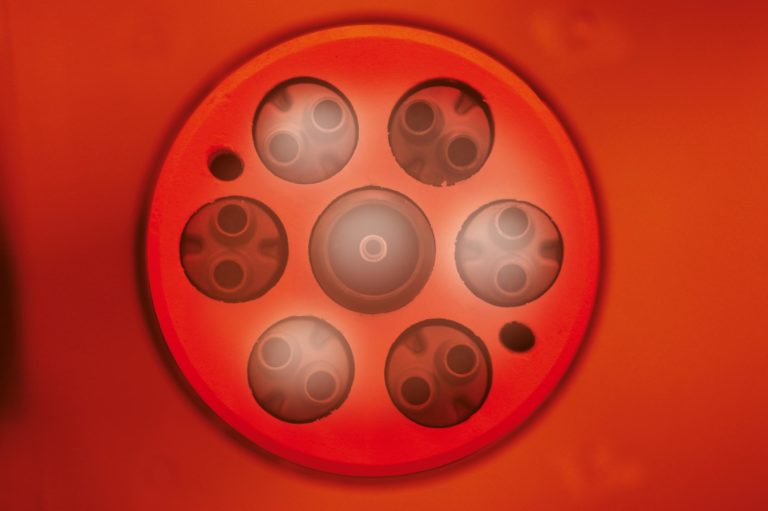

The FLOX® burner REGEMAT® 350 is a self-contained functional unit and eliminates the need for operation in burner pairs, which is otherwise common with regenerator burners. All switching mechanisms are already integrated in the compact unit so that each burner can operate autonomously.

With an operating range at temperatures typically up to 1,250 °C, the REGEMAT® 350 is perfectly suited for direct heating of high-temperature processes, such as forging furnaces.

Due to the extremely high air preheating, the burner achieves maximum energy efficiency with unbeatably low NOx emissions thanks to "FLOX® inside". And of course this burner is also already "Green Gas Ready".

Specifications

Input Rating

Rated power 200 kW FLOX® + 200 kW Boost

Fuel Gas

Natural gas (standard): natural gas H, natural gas L, methane

Other gases (optional): hydrogen, propane, butane and other dust-free, non-aggressive gases

Supply Pressures

Fuel gas: approx. 6000 Pa (60 mbar), ± 5%

Combustion air: approx. 10,000 Pa (100 mbar), ± 5%

Suction pressure: approx. -8000 Pa (-80 mbar), ± 5%

Compressed air 6 bar

Maximum Operating Temperature

Exhaust gas inlet max. 1,250 °C

Flame Supervision

Ionization or UV monitoring

Combustion Mode

Flame/FLOX®

Control Method

On/Off