Drastic CO2 reduction at Rexnord Kette GmbH

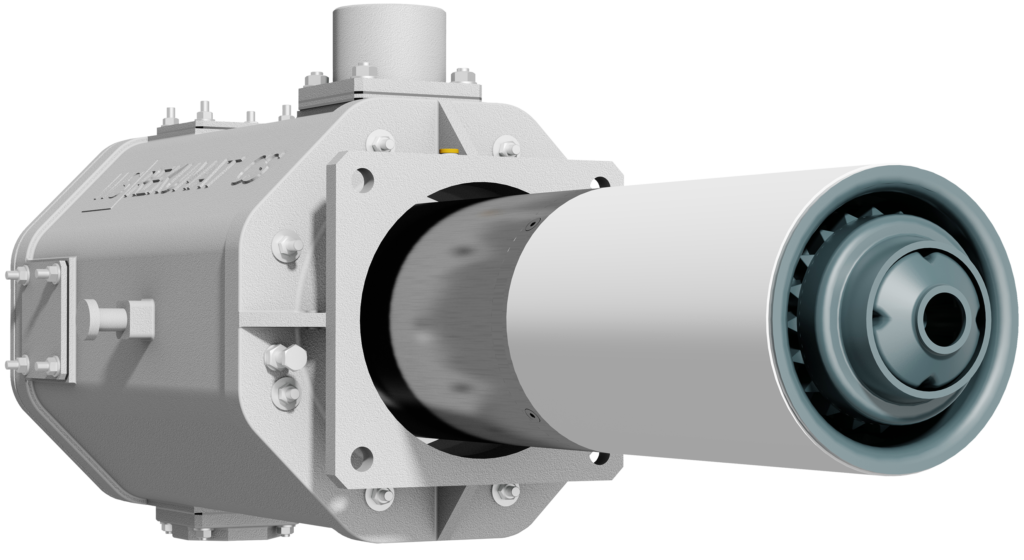

Rexnord Kette GmbH and WS have successfully modernized a belt furnace, reducing the furnace's CO2 emissions by 35%. In addition to new burners with maximum energy efficiency, the optimization of the operating mode also contributes to the CO2 reduction.