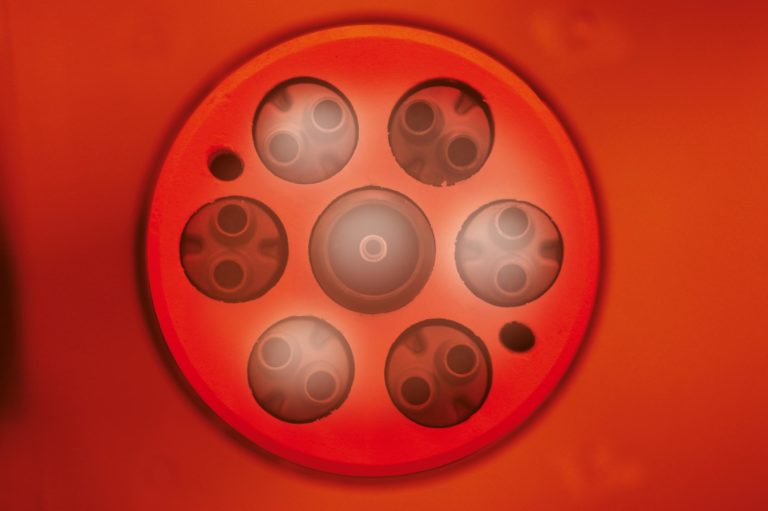

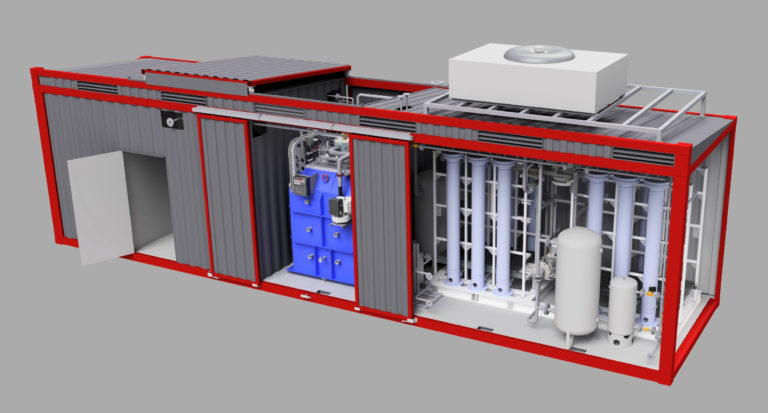

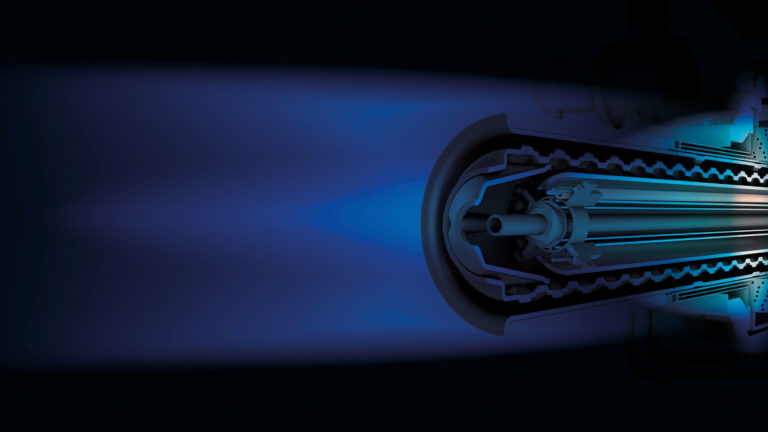

The REGEMAT® 250 revolutionized the world of continuous galvanizing lines shortly after its introduction. With unprecedented efficiency and NOx emissions that make downstream exhaust gas treatment unnecessary even under the strictest regulations.

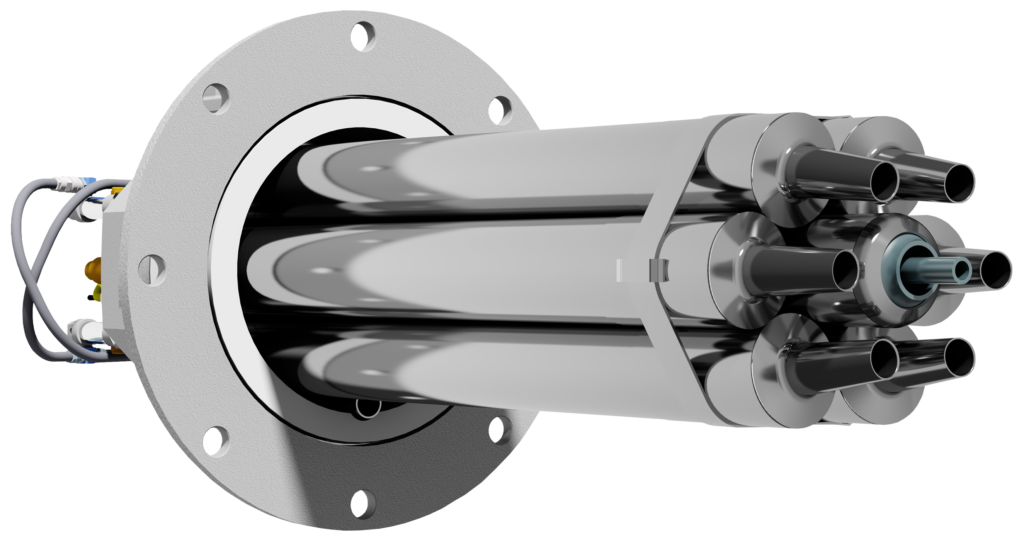

Even today, customers who rely on the REGEMAT® 250 are optimally equipped for all possible future developments. Especially since the burner has all "Green Gas Ready"criteria with flying colors. Thanks to their use in recirculating double P-tubes, these systems are ideally prepared for the future of alternative fuels such as operation with green hydrogen.

With well over 10 years of operating experience of thousands of burners, the REGEMAT® 250 is now proven reference technology for all customers who want a particularly future-proof and highly efficient system.

Specifications

Input Rating

Rated power 140 kW

Fuel Gas

Natural gas (standard): natural gas H, natural gas L, methane

Other gases (optional): hydrogen, propane, butane and other dust-free, non-aggressive gases

Supply Pressures

Fuel gas: 7000 Pa (70 mbar), ± 5%

Combustion air: 8000 Pa (80 mbar), ± 5%

Suction pressure -8000 Pa (-80 mbar), ± 5%

Compressed air 5-6 bar

Maximum Operating Temperature

Exhaust gas inlet max. 1,050 °C

Flame Supervision

UV monitoring

Combustion Mode

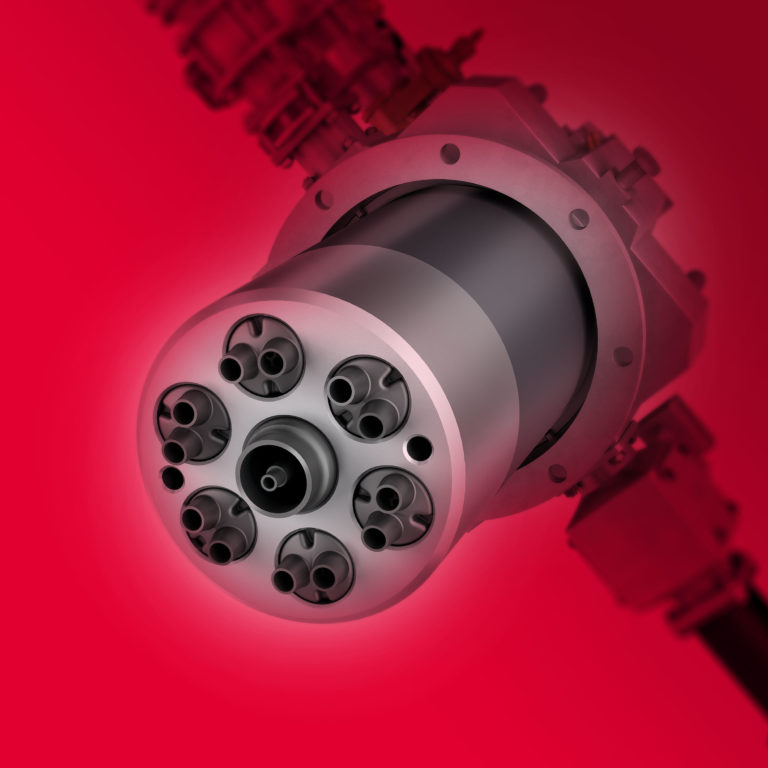

Flame/FLOX®

Control Method

On/Off