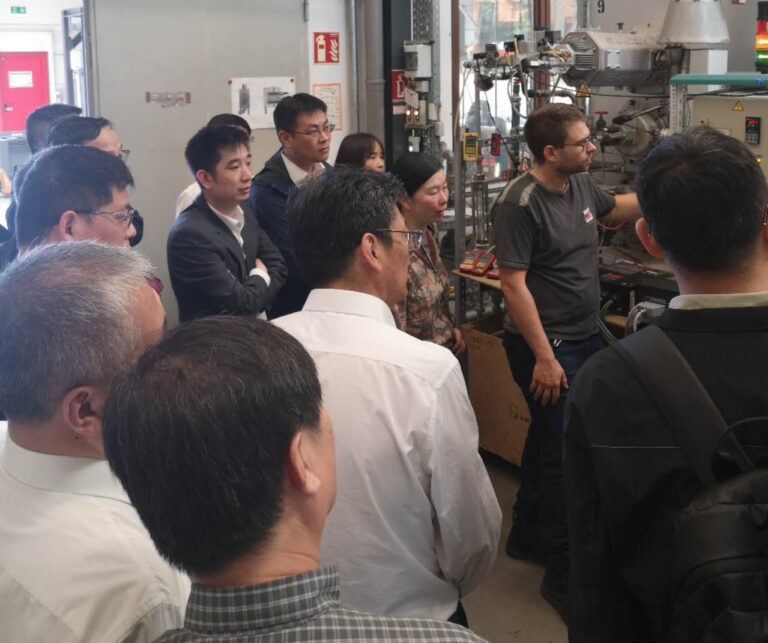

WS Summer party 2024

There was a lot to celebrate at the WS Summer Party 2024. Around 250 guests spent a thoroughly successful day in Renningen in the best weather and found out about the many new developments in the WS Group. Good food and a cold drink or two ensured a great atmosphere and fond memories.