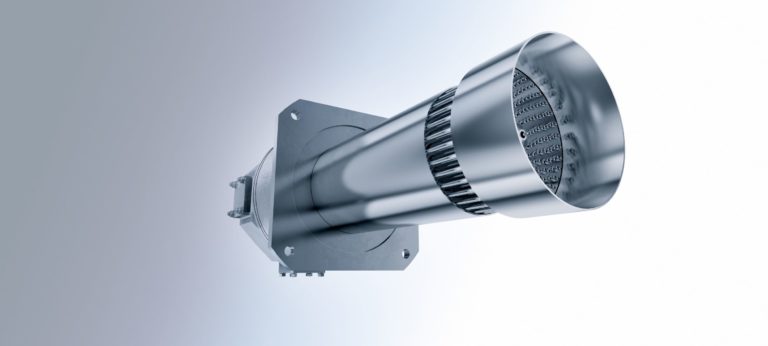

Minister President Kretschmann visits WS in Renningen

Baden-Württemberg's Prime Minsiter Winfried Kretschmann visits WS in Renningen to find out about activities in the field of hydrogen. In addition to the production of green hydrogen from biogas and decentralized ammonia cracking, the high-ranking visit also focuses on the highly efficient and low-emission industrial burners manufactured by WS.